September - October 2018

11

boatingonthehudson.com

Report of Nature Conservancy Billion

Oyster Project, (For those folks really

wanting to study Billion Oyster Project here

is a perfect place to start!)

DESIGNING FOR DEEP WATERS

Different reef projects require different materials. For the

Hudson reefs system, it was important to consider the

fact that these waters are deep and fast moving. Pictured

below, the steel gabion structures provide a strong, current-

resistant 3D environment that facilities reefing. Since this

project is geared toward wild oysters already in the water,

note that shells are empty and will provide homes for wild

oyster babies (larvae).

PHASE 1

The original gabion deployed in 2015 was designed

by Pete Malinowski, New York Harbor School Ocean

Engineering instructor Rick Lee, and Harbor School student

Marisol, and constructed by Harbor School Marine Systems

Technology instructor Clarke Dennis. While the structure

effectively prevented oysters from sinking into the mud (a

common cause of mortality in murky waters), we found that

it could be improved to serve more oysters per foot.

PHASE 2

During the summer of 2017, the Billion Oyster Project

initiated a re-design of the reef gabions, with the goal of

providing more space on the structure where larvae could

set and grow. Ocean Engineering and Marine Systems

Technology students from New York Harbor School

collaborated with Billion Oyster Project to consider various

configurations of materials and submit a proposal to the

Thruway Authority.

The main modifications were:

• A hollow column was added to the middle of the structure,

maximizing surface area available to oysters and other

animals. This is important for three reasons: (1) Oysters will

grow on all available outer surfaces (2) We have seen that

baby oysters (larvae) swim only 4–5 inches into shells as

they’re seeking a shell to attach to (3) One of the profound

benefits of reefs is the 3D habitat that they create. More

surface area means more habitats for oysters and for other

marine species.

• A full-unit steel mesh enclosure replaces eight inner

cubes, which were held in place with zip ties that sometimes

came loose and shifted. Note that the mesh (galvanized

steel) holds the shells in, and outer (raw) steel is for stability

and ease of lifting and moving the structures.

• The original design used a PVC-coated wire mesh insert.

Within three years time, the oysters had reefed up around

this material, growing right through the 1” x 1” openings.

In an attempt to reduce the amount of unnatural materials

added to NY Harbor, we proposed a switch to uncoated

steel mesh, which over several years will break down

without adding pollutants to the water. (And in the long run,

the oysters will cement together and the mesh will no longer

be needed to maintain the structure of the reef.)

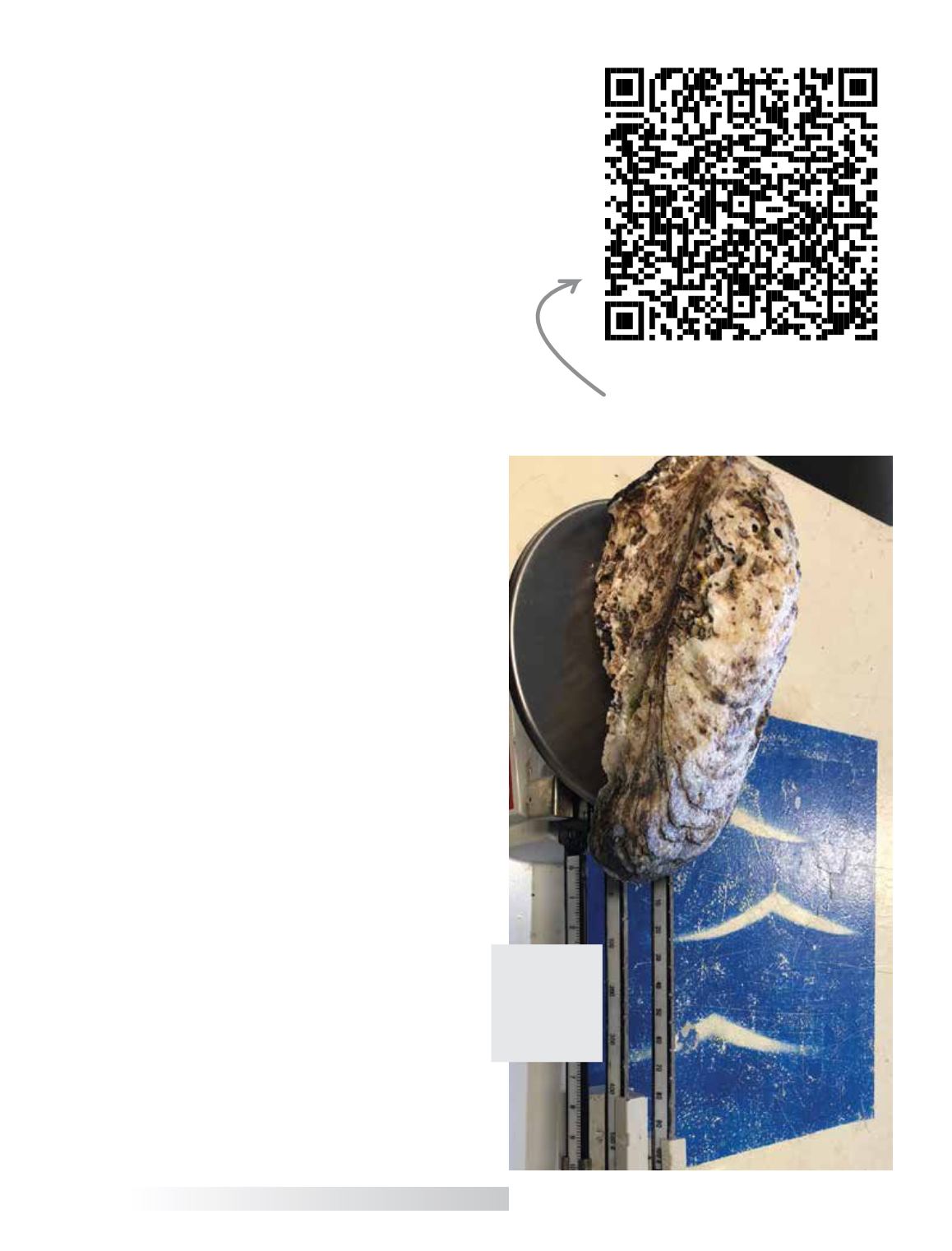

River Project

Photo Huge

Oyster