Holiday 2018

67

boatingonthehudson.com

requires different types of bottom paint. The Epoxy

Barrier can then be applied by rolling or spraying.

Mixing the paint product, timing and temperature

are critical for a good bond. We suggest a professional

to do this work.

At the very minimum a hull should have barrier

coat. In my opinion this is essential if your boat

is kept in the water! A barrier coat needs to be

applied first and is much more important than

bottom paint.

If you apply bottom paint I highly recommend

applying barrier coat first. You’re wasting your

money if you only apply bottom paint!

Marine antifouling protective paint

a.k.a. “Bottom Paint” will keep organisms from

growing on your hull e.g. algae, bacteria, zebra

mussels, etc. There are many types available.

Ablative –

It is soft and wears away quickly.

As the boat moves through the water fresh layers

of paint are constantly being exposed - great

for high marine growth areas. An advantage of

this type is that there is minimal build up and

you can apply this over most other antifouling

paints. I have been told this type does not retain

its antifouling ability for more than 30 days after

being hauled out.

Controlled Solubility Copolymers

–

Partially soluble similar to ablative types. Product

is also good for areas with high concentration

of fouling problems. Boats can be hauled and

relaunched without repainting. Obviously longevity

is related to the thickness of the paint.

Hard antifouling paint –

Dries to a porous film

that leaches out a biocide when in contact with water

to prevent attachment of marine growth. It tends to

lose its effectiveness rather quickly and a hard paint

film remains on the boat. After multiple applications

the surface will build up and after a while it would

need to be removed and reapplied. It is a good

type for racing boats & sailboats that have bottoms

regularly cleaned.

Self-Polishing Copolymer

– contains a

patented resin that reacts with salt water. Product

remains effective whether the boat is sitting at the

dock or is underway. Not recommended for fresh

water use.

Aluminum boat owners please note! Do not

apply bottom paint containing copper directly over

aluminum. The results would be electrolysis upon

contact with the water.

Many boat owners opt to apply these paints on

their own but it’s really best to hire a professional to

insure good protecting results.

Proper hull prep and application is essential or you

will again be wasting your money.

I also recommend that if you trailer your boat, keep

it on the trailer or a boat lift! Get it out of the water!

Don’t let it sit in the water all week long if you only

use it on the weekends!

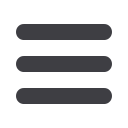

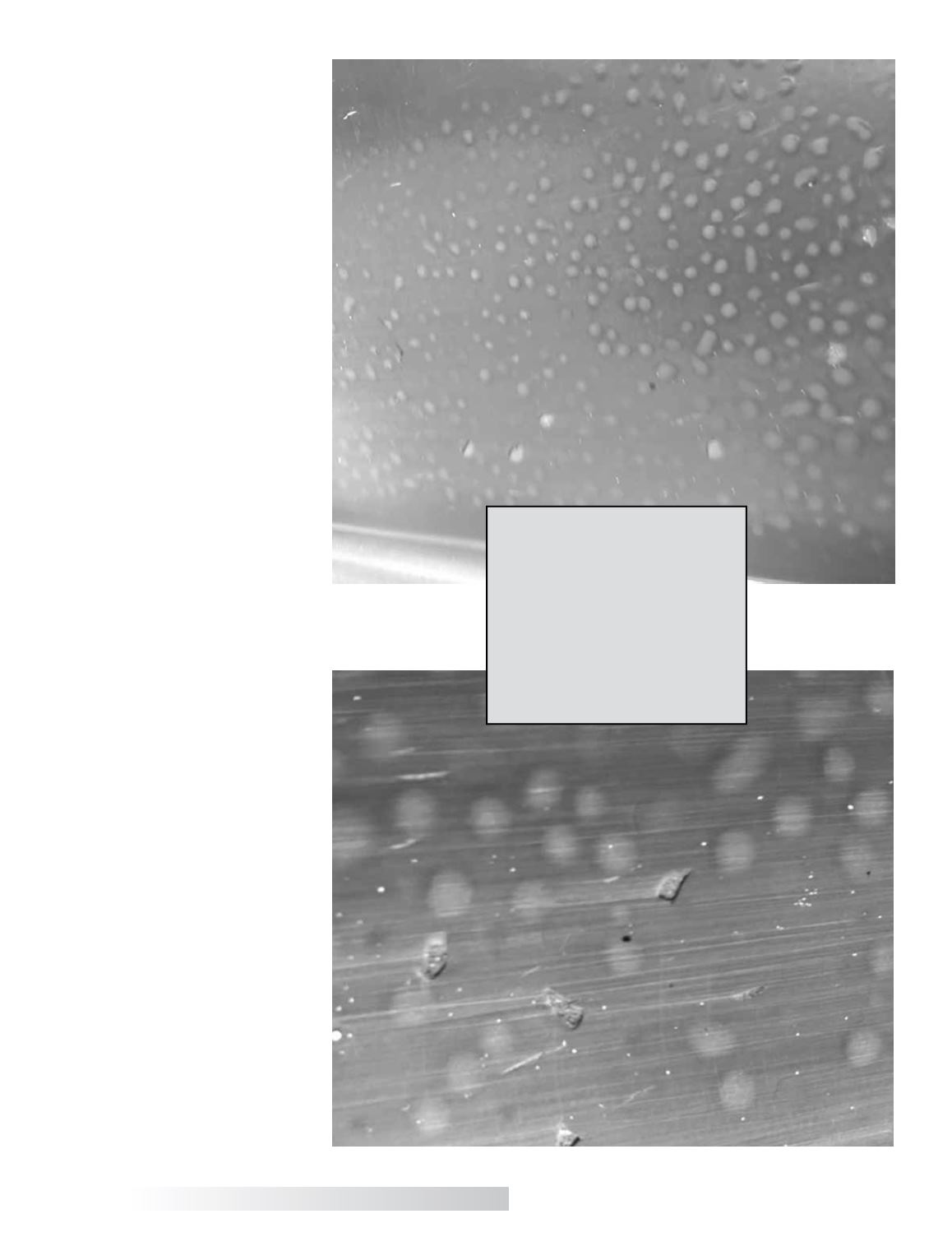

Migrating water seeps into an

area of concentrated water soluble

materials and mixes together -

acids are formed. This acidic pasty

mixture is too thick to go back out

through the precocity in the gelcoat.

The gaseous acid expands, pressure

grows and thus the blister is created

on the surface. All blisters are

formed this way.